COURSE DESCRIPTION

Now that you have completed our Certified Fiber Optic Installer course what is next? The fiber optic market size was valued at 5.41 billion dollars in 2015. This market size is expected to double by 2025. This growth will impact all industries from telecom, Oil & Gas, Military and Aerospace, medical and rail systems. And all of these industries will need trained specialized technicians.

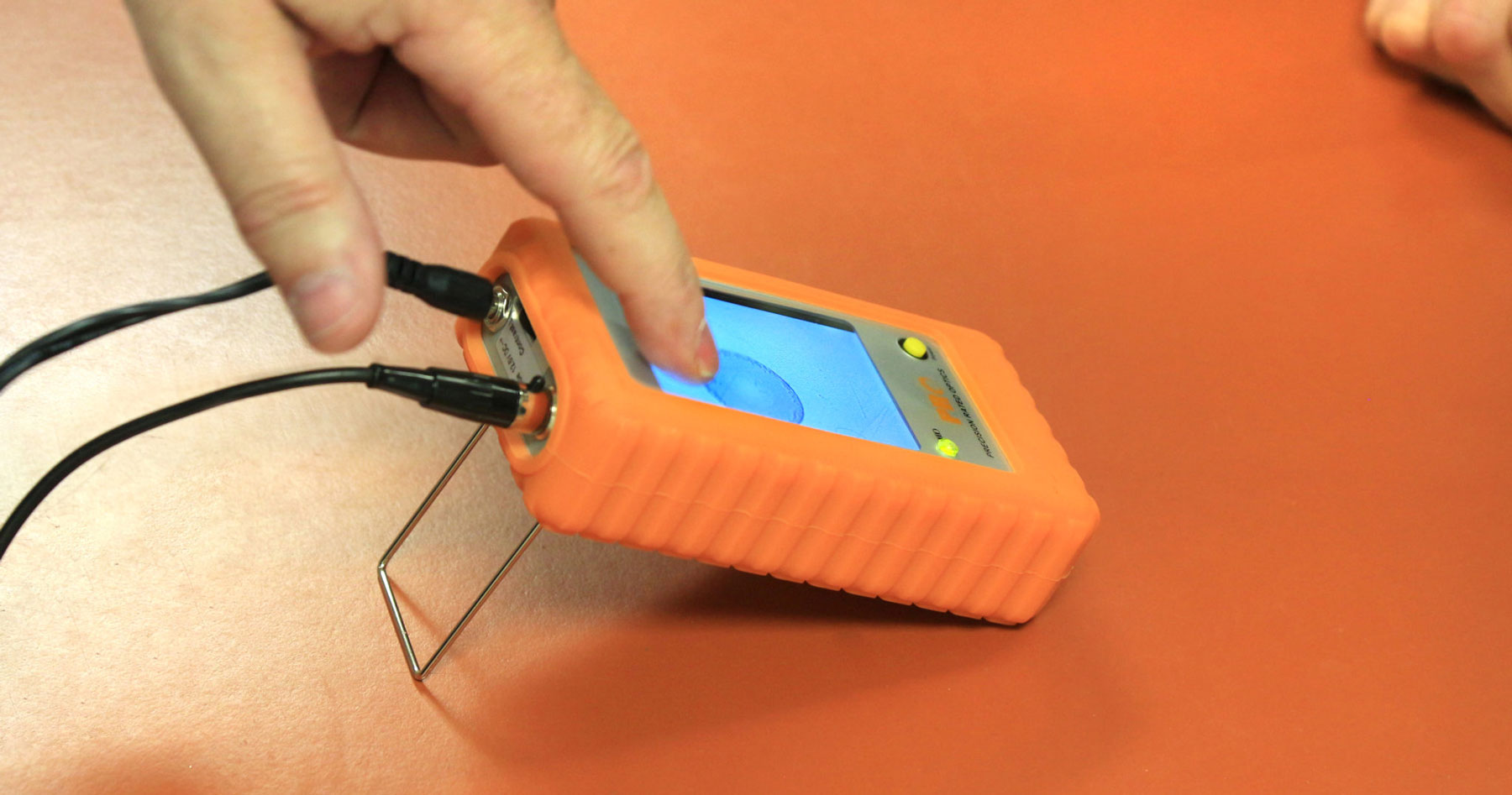

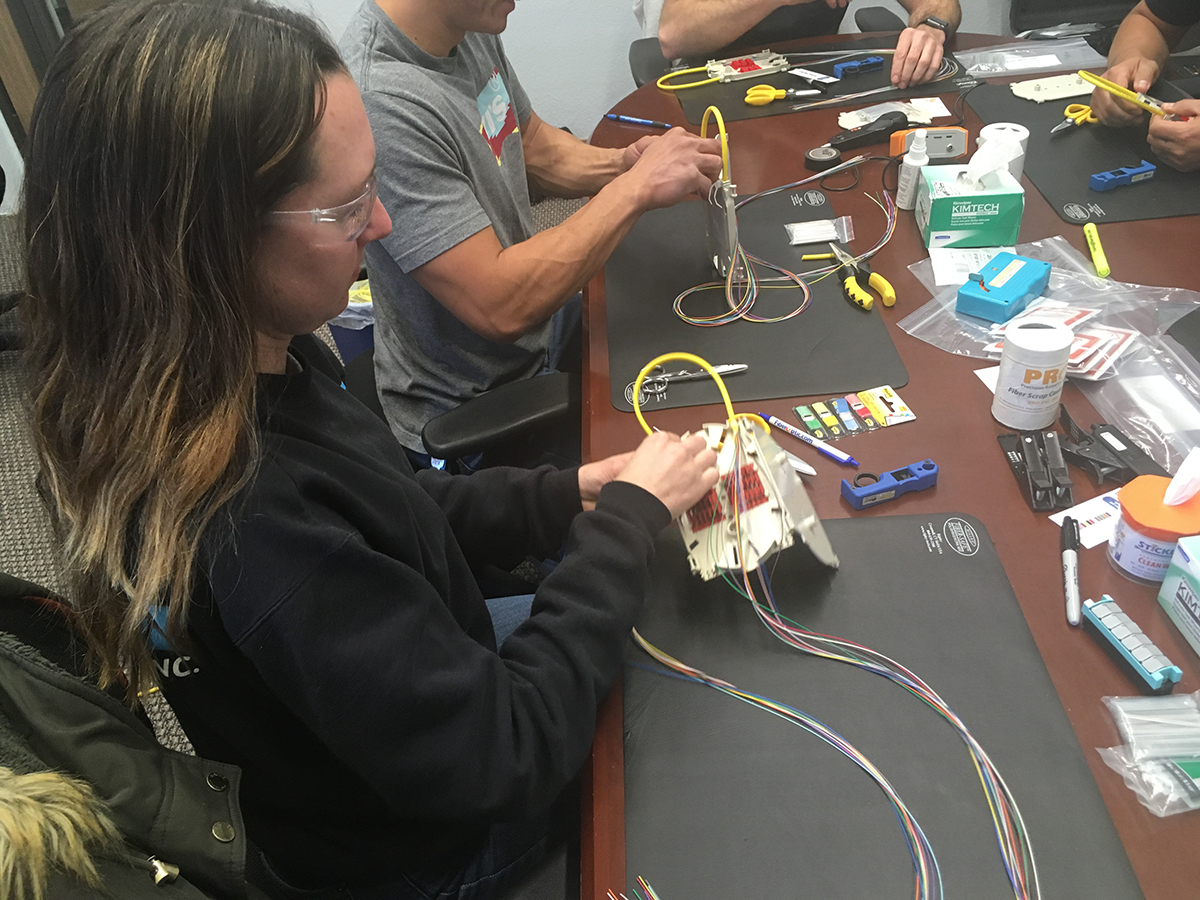

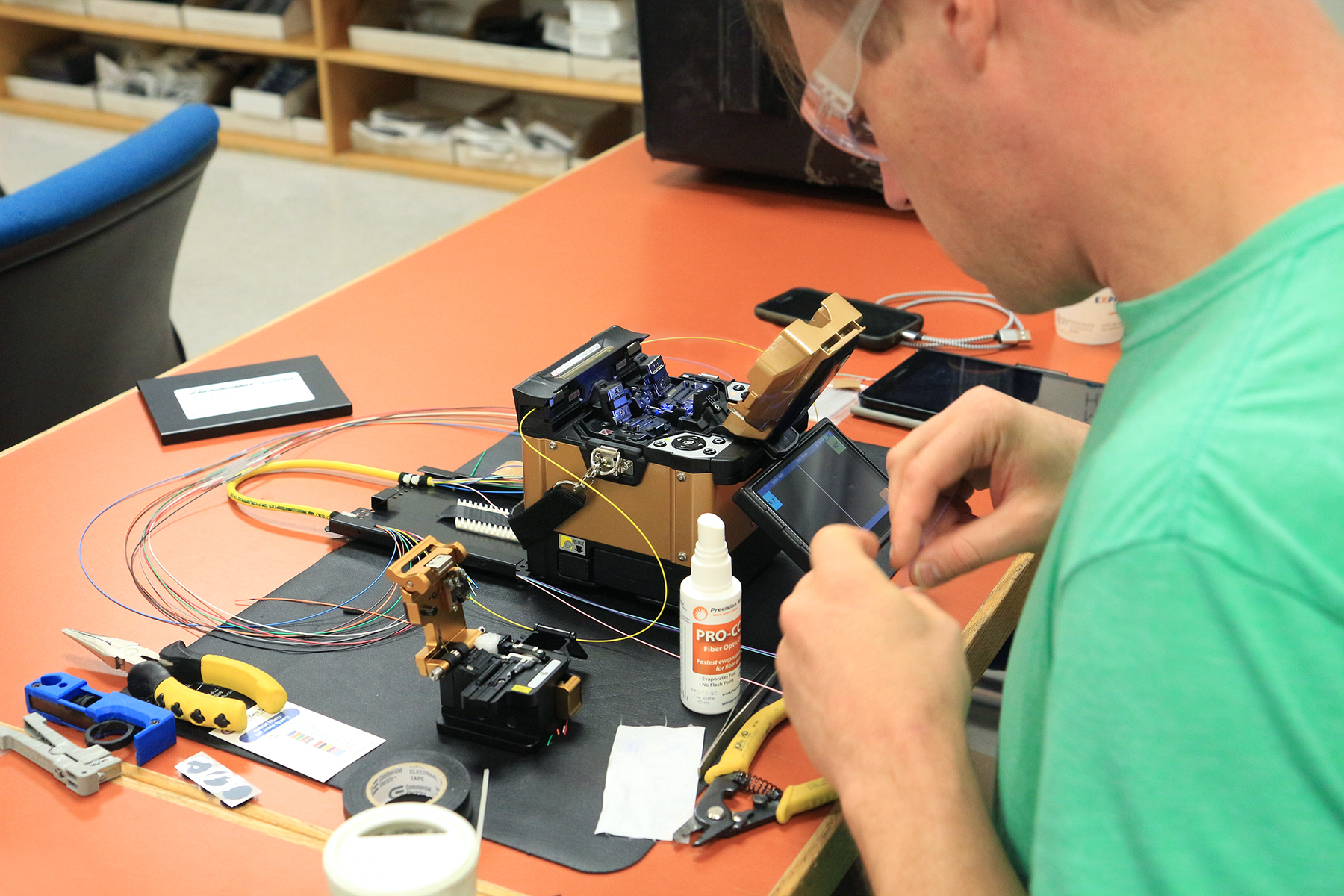

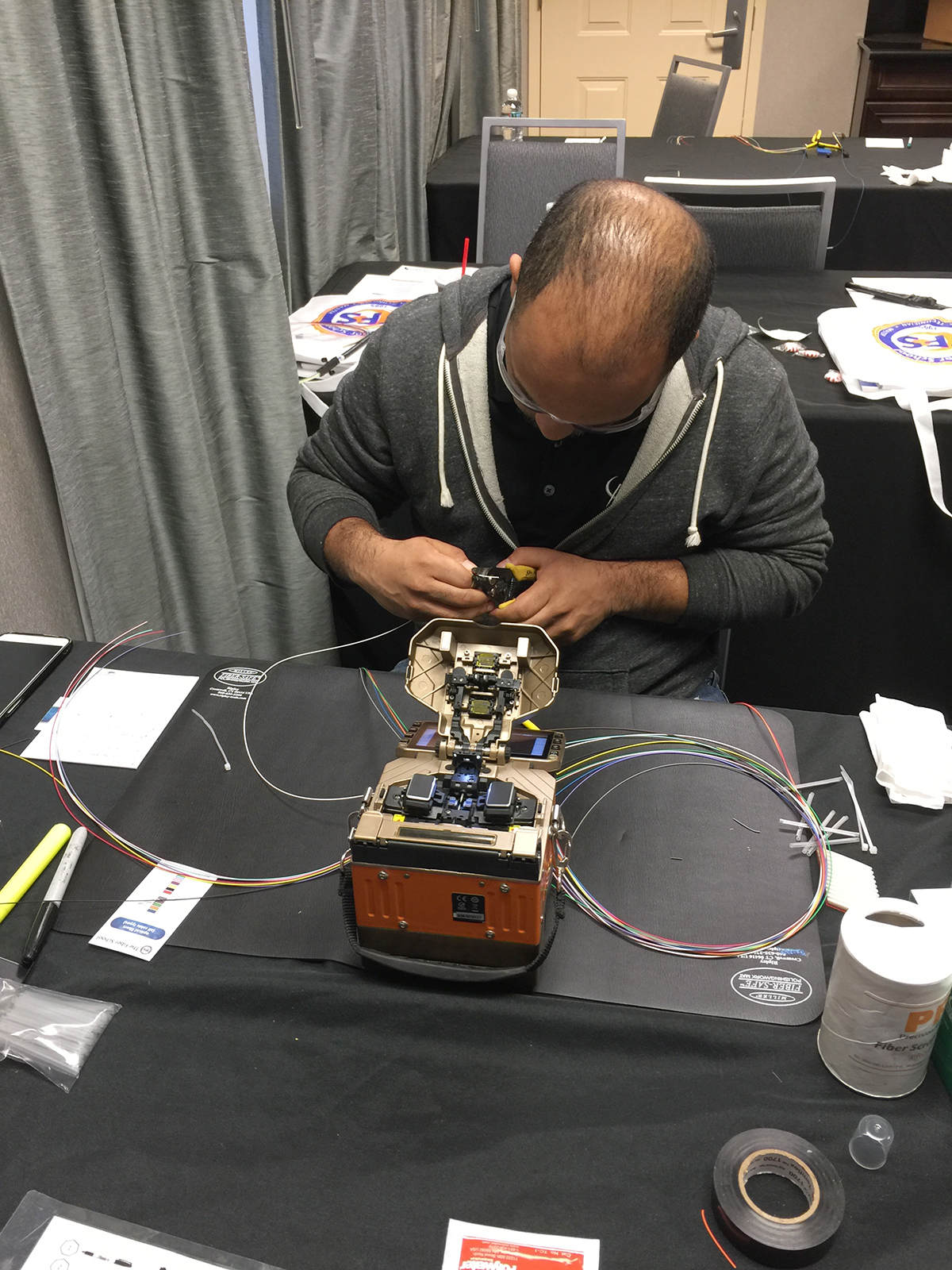

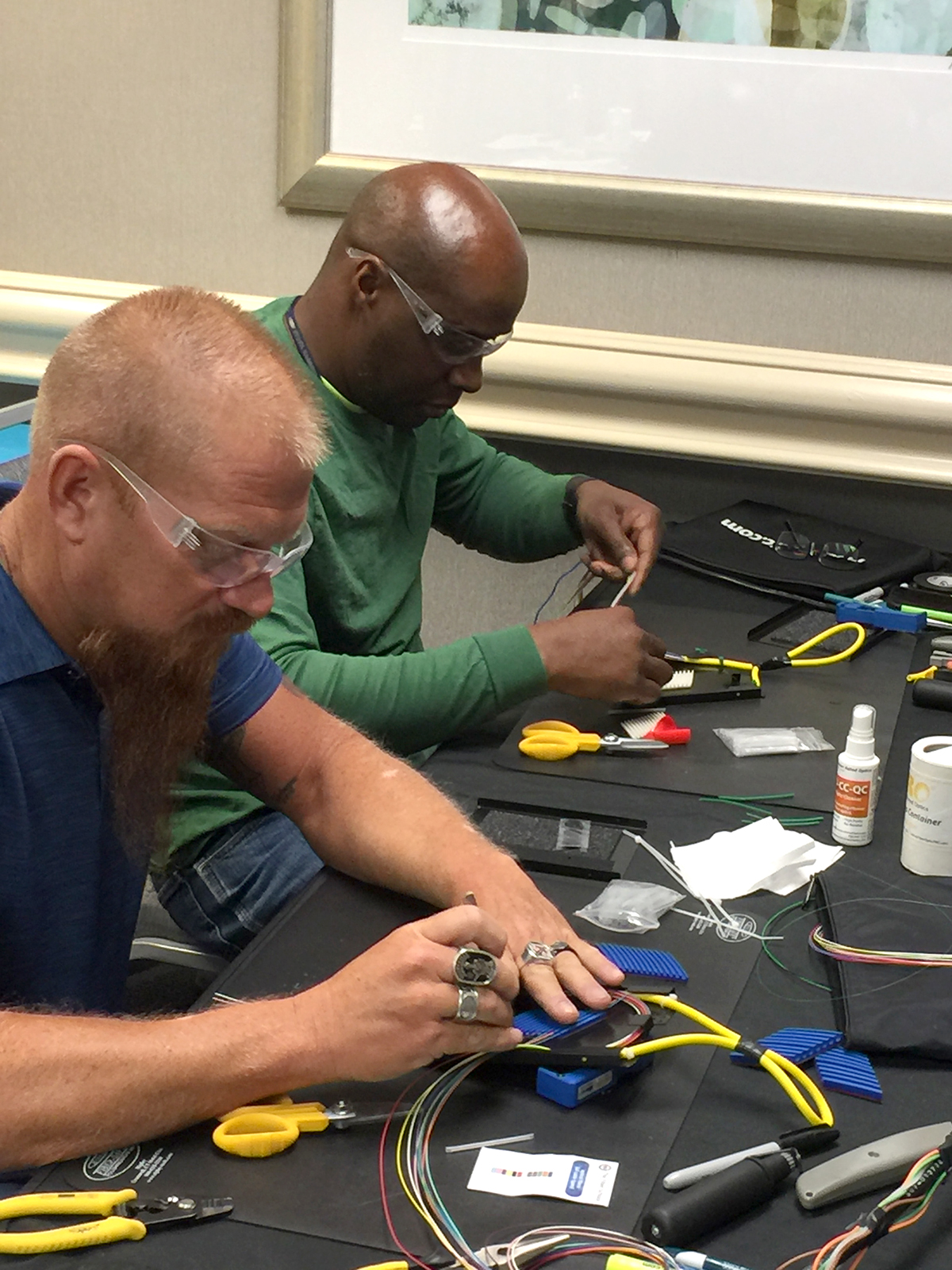

Our technician level courses are the next step in your training. These courses will better position you to be able to advance in your career in the fiber industry. The technician courses are intense and consist of five days of real-world hands-on lab exercises that will build upon the knowledge you have gained in the installer level courses and prepare you for more advanced splicing and testing installations.

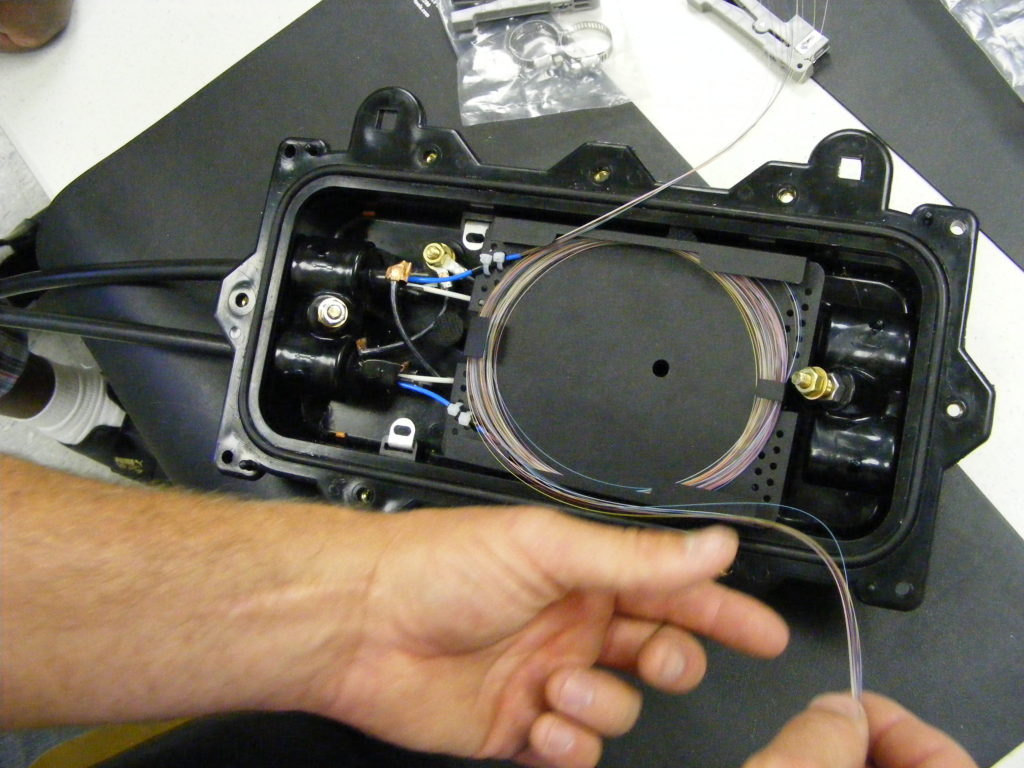

The Fiber Optic Outside Plant Technician course is similar to the Fiber Optic Technician (TR-FOT) course in that it is designed for workers with fundamental fiber optic knowledge or Installer Certification. It focuses specifically on outside plant installations (OSP). OSP includes communications such as building to building or long haul telecommunications (including customer-owned OSP.)

Emphasis is on single mode fiber optic installation and the associated international standards, theory, and practices. This specialized course is a must for any OSP professional. This course also includes an overview of FTTx (“Fiber to the x”) applications (but there is another course specifically for FTTx specialists – TR-FTTX.)

The industry may never see growth like this again, so don’t put off your career. It all starts with a phone call or an email to 877-529-9114 training@fiberoptic.com.